This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Discover previously unimagined capabilities and areas of application for electric actuators with naXture

MetisMotion as a partner

Automation, robotics, digitisation – with you right at the centre!

With naXture, you set new standards in your industry and drive innovation that provides smarter and more sustainable solutions for your customers. Improve existing products and discover competitive advantages faster than others – with MetisMotion as your partner.

Areas of application

Compact solutions for big challenges

-

Highly compact electrification in automation technology

e.g. automated workpiece clamping

which must be compact and efficient enough to allow battery operation or power supply via a BUS system

e.g. ultra-compact workpiece grippers

For use in confined assembly spaces, with precise force control and low inertia – robust and lightweight to optimise the available payload for robotic handlingtasks

-

Actuators for special ambient conditions

e.g. door locks

For aircraft cabin doors requiring high levels of robustness, wide operating temperature ranges and exceptional reliability

e.g. valve controls

For the actuation of control valves that require high positioning accuracy despite high force requirements and strong vibrations – while reliably assuming a safe state in the event of a fault

-

naXture Guide exclusiveActuators for real-time insights into your application

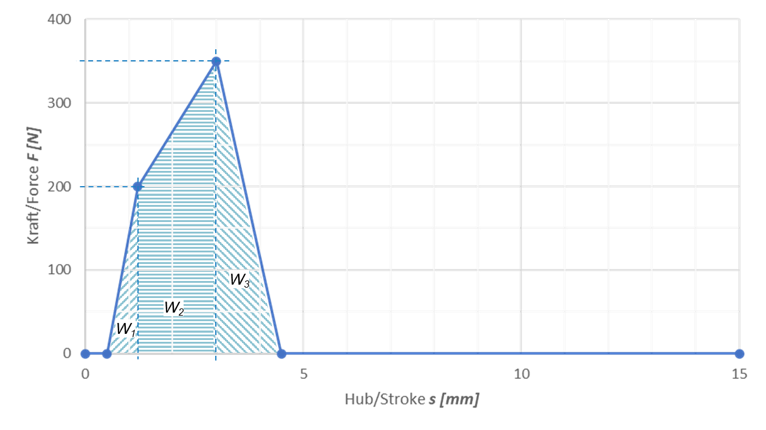

e.g. riveting

Monitor the specification compliance of the riveting process while the rivet is being set. Without additional sensors – for continuous process control.

e.g. status monitoring

Gain insight into the condition of your system and acquire valuable information to plan service intervals more efficiently.

-

Assistance systems

e.g. for production and manufacturing

when working overhead or handling heavy and bulky objects

e.g. prosthetics

Bionic hand prostheses that require sensory capabilities to approximate the movement and gripping action of a human hand as closely as possible

Working with MetisMotion

Expect exceptional results

With MetisMotion, you choose the partner who develops the customised solution for your specific requirements in partnership with you on an equal footing. Discover together with us how your system can develop efficiently and what possibilities our innovative actuator technology has in store for you. A highly motivated development and engineering team awaits you, who will work with you to develop solutions for demanding challenges.

Innovations at MetisMotion

Together we turn your visions into reality

Disruptive technology

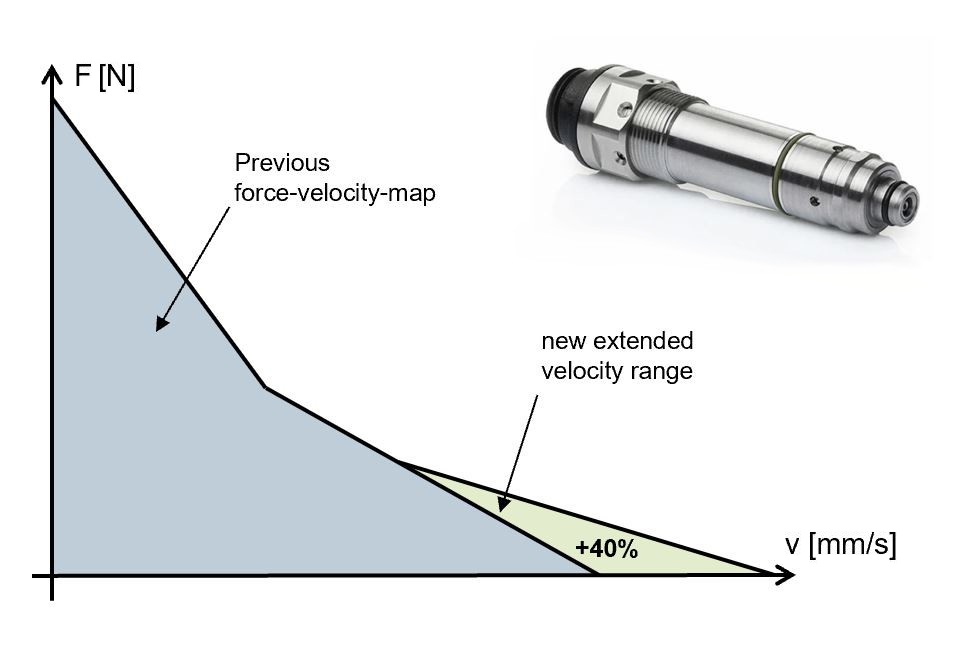

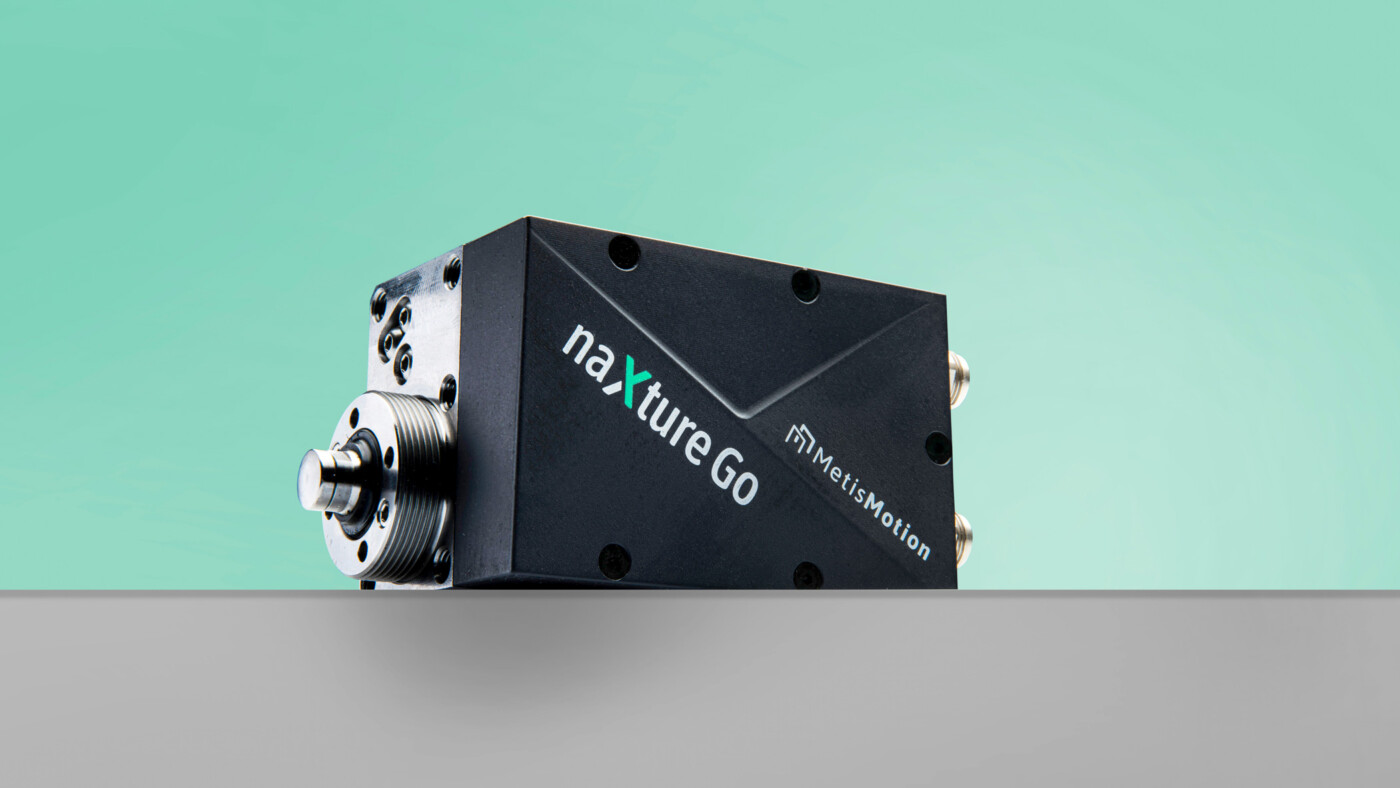

naXture is based on a bio-inspired actuator concept with highly integrated microhydraulic circuits. This allows the advantages of conventional technologies to be combined with future requirements for efficiency, performance, robustness and miniaturisation.

Modular engineering

The modular design of our actuator systems allows them to be adapted to individual environments and performance requirements. Whether as pure replacement for fluidic actuators, in a sensitive closed loop system or as an IIOT device, as a source of force or speed, single-acting or double-acting – the combinations are as diverse as

their areas of application.

InnovationLab

In our competence centre, we combine decades of technological know-how with implementation expertise. Here, ideas mature in a creative environment – always with the aim of designing new concepts that can be quickly implemented and used in industry and that inspire their users.

Blog