This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

naXture unlocks unprecedented capabilities for electrified high-force actuation

naXture in a nutshell

naXture revolutionises the world of actuation

The inspiration for our actuators comes from nature: the characteristics of human muscles. This is the basis for a completely disruptive technology with which we are setting a new standard in the field of electrified actuation – with a performance profile that can be adapted to a wide range of applications. For the first time, naXture allows you to combine maximum efficiency with the capabilities that matter to you in a scalable arrangement. A pioneering actuator, ready for the challenges of Industry 4.0 and at the same time robust enough to withstand even the most demanding environments. And all this in a format that fits in the palm of your hand.

naXture configuration

naXture always offers exactly the skills you need

Are you looking for high-performance actuators for high force or speed requirements in low mechanical power ranges?

Then you will find everything you need in our naXture platform. The modular design allows for scalable functions, which are freely configurable on the basis of standard components.

A selection of the configurable naXture functions includes:

- Stroke, force and speed

- Safety behaviour in case of power loss

- Impedance characteristics

- Actuator geometry and integration

For which force-speed profile should your actuator be optimised? Our sample selection tool uses this design criterion to give you an initial insight into which samples, based on the naXture standard components, are available for you at short notice.

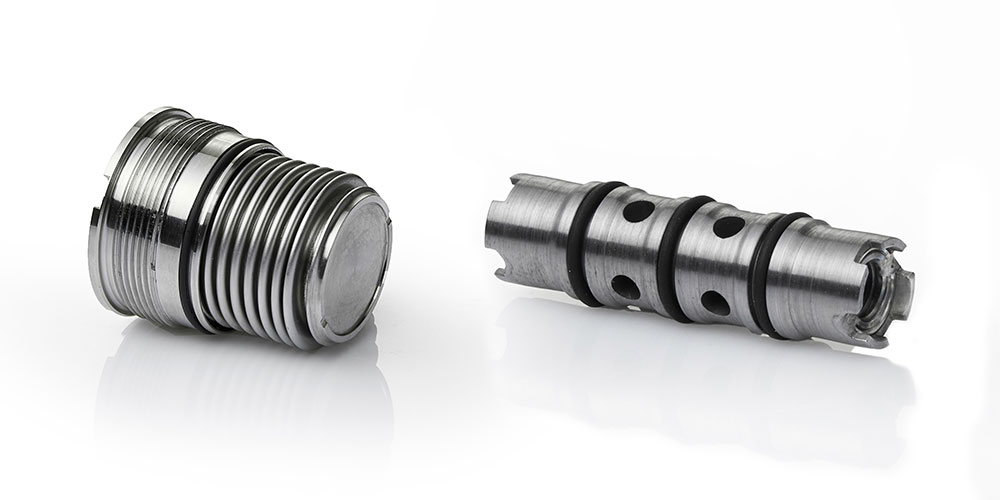

naXture platform

Freely configurable standard modules for your specific actuator solution

naXture family

Find the right solution for your application

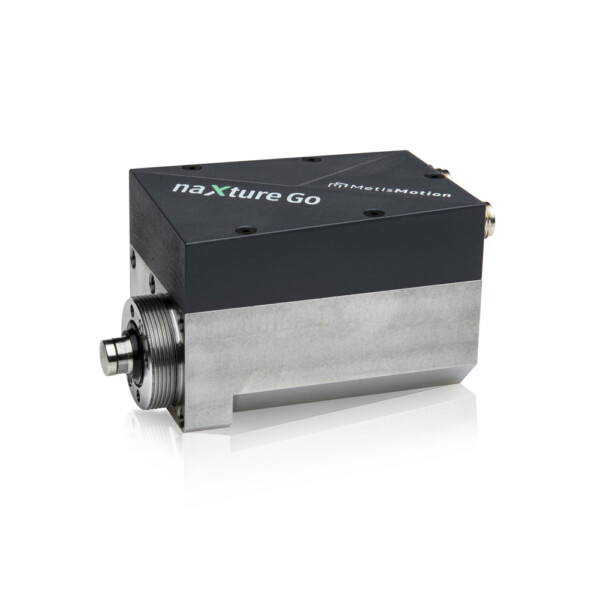

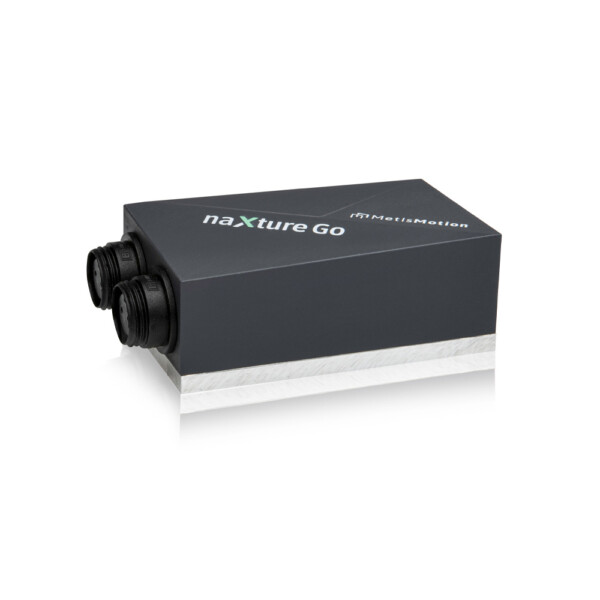

naXture Go

naXture Go is the first actuating solution adapted to your specific needs.

Whether special force, stroke, speed or safety requirements, impedance behaviour or integration into the smallest installation spaces – thanks to the possibility for unique combinations of standardised modules in individual housings, naXture Go is the efficient solution for your specific application.

naXture Guide

naXture Guide is the world’s first actuator with the sixth sense. Building on naXture technology, naXture Guide provides access to the actuator’s inherent self-awareness, opening detailed insight into process parameters and enabling real-time quality control – without any additional sensors. The result is the only actuator with the ability to instantly adapt its behaviour based on situational awareness. This opens up the potential for immediate and thus much more robust, refined and fail-safe control approaches for your individual use cases.

Contact

Which actuation problem can we solve for you?

naXture advantages

Experience the advantages of nature-inspired actuator technology with naXture

Robust and compact

naXture actuators are particularly robust. They stand out thanks to their high force density and their long service life in particularly demanding industrial environments. Even with heavy dirt contamination, high accelerations or extreme temperature ranges, naXture copes perfectly.

Plug & Play

Each naXture actuator consists of standardised functional modules that we configure specifically for you. They can be quickly integrated into your existing manufacturing processes or implemented as a stand-alone system solution – for minimal integration and operating costs and a fast time to market for your solution.

Efficient and sustainable

naXture combines high force density with positioning accuracy and ultra-dynamic movement with up to 75 percent less energy consumption. With our in-house development and manufacturing and our strong regional supplier base, we offer a reliable, scalable and sustainable supply chain.

naXture Guide

exclusive

Self-awareness

naXture Guide – the world’s first actuator with inherent self-awareness – allows real-time insights and perception-driven behaviour without additional sensors. This gives you immediate and therefore much more robust control approaches for online process monitoring, such as fault detection or predictive maintenance.